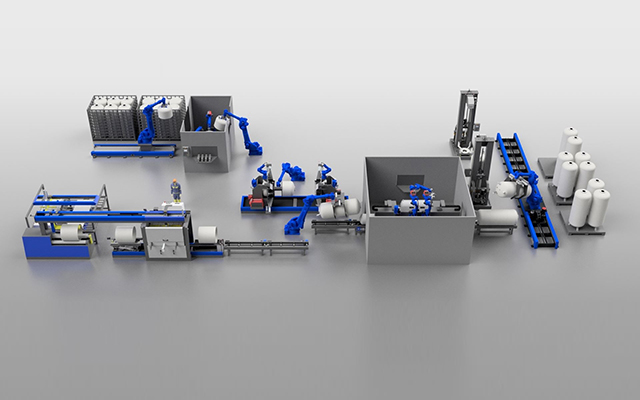

가스탱크 로봇 생산라인

The production line for gas tank robots is a highly sophisticated and meticulously designed system that integrates advanced robotics, automation, and precision engineering to manufacture robotic systems specifically designed for handling and inspecting gas tanks. This production line is a testament to modern manufacturing capabilities, ensuring efficiency, accuracy, and safety throughout the entire process.The production process begins with the design and prototyping phase, where engineers utilize cutting-edge CAD (Computer-Aided Design) software to create detailed blueprints of the gas tank robots. These designs are optimized for functionality, durability, and ease of maintenance. Once the design is finalized, the production line transitions to the fabrication stage. Here, high-precision CNC (Computer Numerical Control) machines are employed to manufacture the robot's structural components, ensuring that each part meets stringent quality standards.The assembly phase is where the production line truly showcases its automation prowess. Robotic arms, guided by advanced AI algorithms, meticulously assemble the various components of the gas tank robot. These robots are equipped with sensors and cameras to ensure precise alignment and correct installation of each part. The assembly process is closely monitored by quality control systems that detect and rectify any deviations from the design specifications.After assembly, the gas tank robots undergo rigorous testing and calibration. This phase involves simulating real-world conditions to ensure that the robots can handle gas tanks safely and efficiently. The testing process includes checking the robot's mobility, grip strength, sensor accuracy, and overall performance. Any issues identified during testing are addressed promptly to ensure that the final product meets the highest standards of reliability and safety.The production line also incorporates advanced logistics systems to manage the flow of materials and components. Automated guided vehicles (AGVs) transport parts between different stages of the production process, minimizing human intervention and reducing the risk of errors. Additionally, the production line is equipped with real-time monitoring systems that track the progress of each robot through the manufacturing process, providing valuable data for continuous improvement.Safety is a paramount concern in the production of gas tank robots. The production line is designed with multiple safety features, including emergency stop mechanisms, protective barriers, and advanced sensors that detect and prevent potential hazards. Workers are provided with comprehensive training to operate the equipment safely and effectively.In conclusion, the production line for gas tank robots is a marvel of modern engineering, combining advanced robotics, automation, and precision manufacturing to create highly reliable and efficient robotic systems. This production line not only ensures the highest quality standards but also prioritizes safety and sustainability, making it a benchmark in the field of industrial automation.

제품

범주:

가스탱크 로봇 생산라인

-

가스탱크 로봇 생산라인

분류: 가스탱크 로봇 생산라인조회수: 78번호:릴리스 시간: 2025-09-08 11:21:33에이가스 탱크 로봇 생산 라인LPG 실린더, 프로판 탱크, 천연가스 용기, 산업용 저장 탱크, 가정용 가스 실린더 등 다양한 압력 용기를 생산하도록 설계된 고도로 전문화된 자동화 제조 시스템입니다. 이 탱크는 주거용 요리, 난방, 산업용 연료 공급, 화학 처리 및 에너지 저장에 널리 사용됩니다.전통적인 가스 탱크 생산 방법은 수동 용접, 절단, 검사에 크게 의존했기 때문에 불일치, 인적 오류 및 안전 위험이 발생하기 쉽습니다. 안정적이고 안전한 가스 저장에 대한 수요가 전 세계적으로 증가함에 따라 제조업체는 점점 자동화로 전환하고 있습니다. 통합하여로봇 공학, CNC 절단, 지능형 용접, 자동 조립 및 비파괴 검사(NDT), 로봇식...

뉴스

범주:

검색 결과가 없습니다!

케이스

범주:

비디오

범주:

검색 결과가 없습니다!

다운로드

범주:

검색 결과가 없습니다!

모집

범주:

검색 결과가 없습니다!

추천 제품

검색 결과가 없습니다!

왓츠앱

왓츠앱 핸드폰

핸드폰