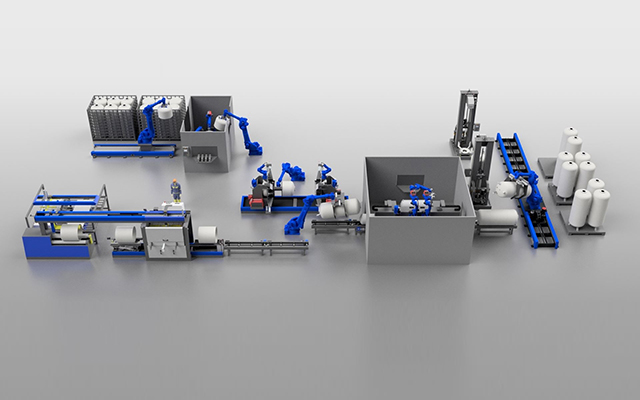

로봇 가스탱크 생산라인

A robot gas tank production line is a highly automated manufacturing system designed to produce gas tanks with precision, efficiency, and consistency. This advanced production line integrates robotics, computer-controlled machinery, and specialized equipment to streamline the entire manufacturing process, from raw material handling to final product inspection. The use of robotics ensures high-quality output while minimizing human error and reducing production time.The production process begins with the preparation of raw materials, typically metal sheets or composite materials, which are cut and shaped into the required dimensions using automated cutting and forming machines. Robotic arms equipped with specialized tools handle the material with precision, ensuring uniformity and accuracy in each component. These robots are programmed to perform repetitive tasks with minimal variation, which is critical for maintaining product consistency.Next, the shaped components are assembled into the gas tank structure. Robotic welding systems are employed to join the parts securely, using techniques such as spot welding or laser welding to ensure strong and leak-proof seams. The robots are equipped with sensors and vision systems to monitor the welding process in real-time, detecting any defects or inconsistencies and making adjustments as needed. This level of automation ensures that every gas tank meets stringent safety and quality standards.After assembly, the gas tanks undergo a series of finishing processes, including cleaning, coating, and painting. Automated systems handle these tasks with precision, applying protective coatings and paint layers evenly to enhance durability and corrosion resistance. Robots are also used to inspect the finished products for any surface imperfections or defects, ensuring that only high-quality gas tanks proceed to the next stage.The final step in the production line is quality control and testing. Advanced robotic systems conduct pressure tests, leak tests, and structural integrity checks to ensure that each gas tank complies with industry regulations and safety standards. Any defective units are automatically identified and removed from the production line, while approved tanks are prepared for packaging and shipment.The integration of robotics in the gas tank production line offers numerous advantages, including increased productivity, reduced labor costs, and improved product quality. Additionally, the use of automation minimizes the risk of workplace injuries by handling hazardous tasks such as welding and material handling. Overall, a robot gas tank production line represents a cutting-edge approach to manufacturing, combining advanced technology with precision engineering to deliver reliable and high-performance gas tanks for various applications.

제품

범주:

가스탱크 로봇 생산라인

-

가스탱크 로봇 생산라인

분류: 가스탱크 로봇 생산라인조회수: 78번호:릴리스 시간: 2025-09-08 11:21:33에이가스 탱크 로봇 생산 라인LPG 실린더, 프로판 탱크, 천연가스 용기, 산업용 저장 탱크, 가정용 가스 실린더 등 다양한 압력 용기를 생산하도록 설계된 고도로 전문화된 자동화 제조 시스템입니다. 이 탱크는 주거용 요리, 난방, 산업용 연료 공급, 화학 처리 및 에너지 저장에 널리 사용됩니다.전통적인 가스 탱크 생산 방법은 수동 용접, 절단, 검사에 크게 의존했기 때문에 불일치, 인적 오류 및 안전 위험이 발생하기 쉽습니다. 안정적이고 안전한 가스 저장에 대한 수요가 전 세계적으로 증가함에 따라 제조업체는 점점 자동화로 전환하고 있습니다. 통합하여로봇 공학, CNC 절단, 지능형 용접, 자동 조립 및 비파괴 검사(NDT), 로봇식...

뉴스

범주:

검색 결과가 없습니다!

케이스

범주:

비디오

범주:

검색 결과가 없습니다!

다운로드

범주:

검색 결과가 없습니다!

모집

범주:

검색 결과가 없습니다!

추천 제품

검색 결과가 없습니다!

왓츠앱

왓츠앱 핸드폰

핸드폰